With the production of Tesla's Gigafacery in Shanghai, the localization of its parts was also launched. Model 3 began to select domestic high-quality suppliers and high-quality parts and components in the supply chain, so that Tesla cars could be recognized by more and more consumers. With the fierce competition of domestic new energy vehicles, increasing the range of new energy vehicles has always been a core issue of great concern to the majority of consumers, while vehicle lightweight is the best way to improve the range and reduce energy consumption.

Tesla model 3

In recent years, Honicel has been committed to promote cellular materials in the direction of the automotive lightweight technology development and application of continuous and various car manufacturers in the world, maintained close relations of cooperation, to provide high quality cellular materials of automobile production enterprises, for the automotive lightweight technology contributed unique solutions.

Terminal automobile manufacturers using Honicel honeycomb materials

With the development of the new energy vehicle market, the pain points in the range of new energy vehicles are becoming more and more prominent, so there are higher requirements for the lightweight design of vehicles. It is reported that if the weight of pure electric vehicles is reduced by 10kg, the driving range can be increased by 2.5km. Therefore, one of the main development direction of automobile industry is the lightweight materials, aluminum alloy frame, ultra-thin high strength steel plate, carbon fiber body, honeycomb composite materials and so on are lightweight technology development path, relying on lightweight technology can reduce car quality, reduce fuel consumption, is the one of main measures to realize energy conservation and environmental protection. Tesla, as a leader in electric vehicles, has more stringent weight control, and honicel's honeycomb advantage lies in reducing mass.

Tesla tail box version with Honicel honeycomb material

Using honeycomb material as automotive interior decoration can not only ensure the strength of the material, but also achieve the maximum degree of lightweight structure. For the automotive industry, the compressive strength of honeycomb materials provided by Honicel is generally more than 5kg/cm², that is, one square meter can bear more than 50 tons of pressure, while its mass is less than 1kg. Therefore, more and more automotive interior parts begin to use honeycomb structural materials.

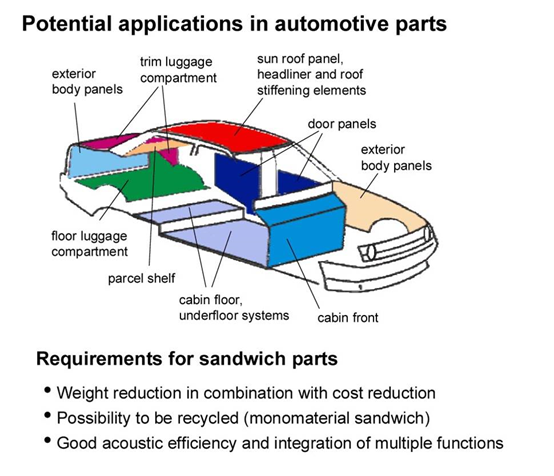

Commonly used automotive honeycomb panel is sandwiched with honeycomb core material sandwiched between two sides of glass fiber felt and made of high strength resin as adhesive. In honeycomb composite board manufacturing process, the layers of material by automatic production line and robot complete combination, spray adhesive, the whole process of high temperature moulding and stripping, without human intervention, the honeycomb composite material production into the automatic and intelligent production mode, bid farewell to the traditional manual production of honeycomb composite plate backward mode of production, Also makes the automobile honeycomb panel production began to enter the industrialization, scale and intelligent production mode. Honeycomb structure interior decoration products made in this way have stable structure, strong resistance to temperature changes, and excellent quality, which fully embodies the structural characteristics of honeycomb composite materials of rigidity, strength, stability and light. At present, this kind of lightweight and high-strength honeycomb composite plate is mainly used for interior decoration such as car trunk bottom plate, coat and hat rack, sunshade and skylight sunshade, and its potential more applications need to be further explored.

Potential application of lightweight composite hybrid vehicles

Honicel as the earliest to the introduction of the honeycomb material of high-tech enterprises in our country, starting in 1995, has been committed to honeycomb materials in various fields of application and promotion, in the field of automobile is also one of the earliest on research and development of enterprises, as early as 2008 lotus lselection of honeycomb interior parts applied for auto patent 'a car tail box with slide mat', In 2012, the r&d project of Passenger Car Honeycomb Structural Panel and Large-scale Industrialization was selected into the 'Guangdong High-tech Zone Development Guide Special Plan' and completed all the R&D and mass production tasks in 2015.

Honicel patent and honeycomb composite board structure drawing

At present, Honicel also claim to the interior parts in automotive industry, satisfy the requirement of formaldehyde and VOC in cases, continuous research and development, low odor and no aldehyde products at the same time also for new energy vehicles to provide more lightweight technology solutions, Honicel will go all out, will be more new products and excellent technical solutions to provide more car companies. Grasp the future, common development, forge ahead!