Honicel Honeycomb Group

Guangzhou Honicel Honeycomb Material Co., Ltd. is a high-tech new material enterprise founded in 1995 by Dr. Wang Wenming, a returnee and Honicel International Co., LTD.

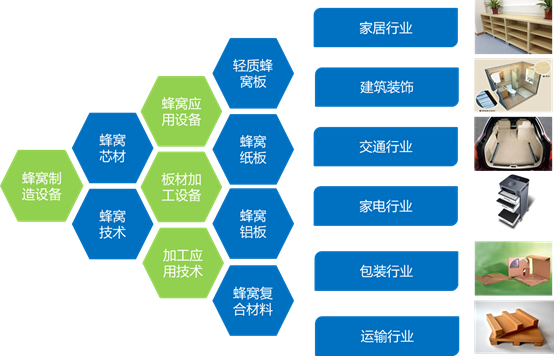

Honicel is the pioneer and leader of honeycomb material structure. After 26 years of development, Honicel has established a set of high-tech honeycomb material system with Chinese characteristics.

With 20 years of continuous development and innovation, Honicel's patented products and technologies cover a complete industrial chain from honeycomb core materials, to honeycomb processing equipment, and then to honeycomb panels, providing systematic solutions for furniture, automobile, packaging, construction and other industries.

With its excellent physical performance, by the majority of consumers trust and support.

Honicel has always been committed to creating resource-saving and environment-friendly lightweight materials. Through continuous research and innovation, honicel's latest research and development of honicel rock plate has hit the market.

Different from other rock plate on the market, Honicel rock plate is a new type of composite structure plate, it will be high performance aluminum core glass fiber honeycomb material and ultra-thin rock plate with structural adhesive paste, after high temperature and high pressure composite formed a new type of composite structure plate.

As a rising supernova of SLATE, it is widely discussed in the industry.

Honicel rock slab

Honicel rock plate is a special type of ceramic rock plate reinforced by honeycomb structure. It combines high-performance aluminum core glass fiber honeycomb material developed by Honicel with ultra-thin rock plate, and makes a new type of honeycomb structure rock plate composite material, referred to as 'Honicel rock plate' after high temperature and high pressure.

Characteristic

The new composite structure-Honicel rock slab has the following

characteristics

| Light weight, high strength, good bending resistance | Honicel rock plate surface has the beautiful appearance of rock plate and hard fireproof performance, but also provides the honeycomb material with light weight, high strength and good bending resistance characteristics, such as 12mm thickness honicel rock plate quality is only 9KG/m2, only 1/3 of the same thickness of rock plate. |

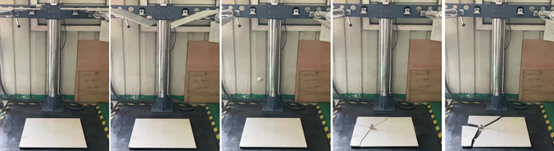

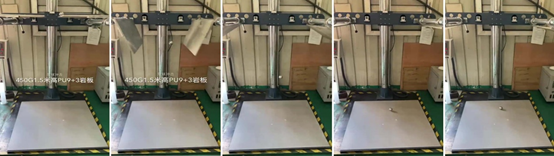

| Impact resistance, easy processing, transportation and installation | After the impact test of 450 grams steel ball, the 12mm honicel rock plate will not break when the ball falls at a height of 1.5 meters, improving the impact resistance of the rock plate, making the ultra-thin rock plate easier to use in the process of transportation, processing and installation, saving the installation time and reducing the comprehensive cost. |

| Green and flame retardant | Honicel rock board is 'zero formaldehyde' decorative plate, its fire rating has reached the building materials fire rating A2, is non-combustible material, but also zero formaldehyde quality environmental protection plate. |

| Low coefficient of expansion | Honicel rock plate adopts glass fiber composite structure with expansion coefficient close to rock plate, which makes honicel rock plate not easy to appear deformation, cracking, delamination and other phenomena. |

| Moistureproof and mothproof | Honicel rock plate is not afraid of water and wet environment, with excellent moisture-proof, waterproof and moth-proof performance.

|

| Sound insulation | Because the honeycomb structure has good heat insulation, sound insulation and heat preservation performance, the Honicel rock plate thus obtains better sound insulation, heat insulation and heat preservation performance than the ordinary rock plate.

|

Test

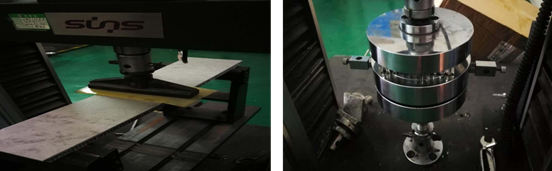

Bending resistance test

Comparative test of impact resistance between ordinary slab and Honicel composite slab

Processing contrast test of common and honicel slabs

Formaldehyde test report of Honicel honeycomb panel

Fire rating test report of Honicel rock slab

Application of Honicel slab

Honicel rock plate relies on the enhancement of honeycomb technology to make up for the weakness and pain point of the fragile of ordinary rock plate, which not only improves the impact resistance and safety of the rock plate, but also is more convenient for processing, transportation, installation and use. We believe that Hollysun plate has a wide range of applications:

1. Prefabricated decoration of wainscoting, background wall, ceiling and floor decoration;

2. Kitchen counter panels, cabinet doors, closet doors and doors for indoor homes;

3. Exterior wall decoration of buildings, landscape decoration of public buildings and advertising boards, etc.

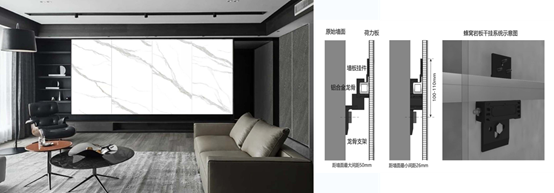

The weight of 1000x3000mm honicel rock plate is only 27KG, light weight, small deformation, impact resistance, easy installation, can be easily used for dry-hanging installation of assembled wallboard.

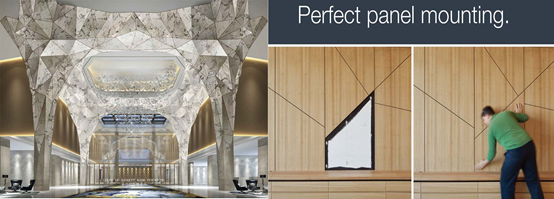

The installation of irregular slabs is a relatively difficult engineering project, and the Honicel dry-hanging system provides a dry construction solution that is relatively easy to install.

The weight of 1200x2600mm honicel rock slab is only 28KG, and it adopts dry hanging mode, which can be used for fast assembly of rock slab background wall, prefabrication in factory, quick installation on site, saving time and effort.

In rock plate application, at the top of the decoration in the form of a wet stick has been the difficulties faced by interior renovation, especially when using the thickness of the thicker rock plate is more difficult, and the top of the rock plate lightweight is the top one of the important measures of prefabricated construction, Honicel high-strength lightweight properties of rock plate can perfectly solve the problem.

Honicel overhead ground system supported by high-strength fiberglass honeycomb panel and floor of feet, the height of the ground at the grass-roots level can pass at any height adjustment for the weight from foot to foot, especially the ground at the grass-roots level can be from the top of the floor after the installation is completed fine-tuning the height of the weight from foot to foot, ensure that the height of the ground can be precise control in the height of the preset range, Then you can directly paste ceramic slabs and other ground decoration materials.

For the assembly construction of the toilet, Honicel has developed a special high foot support leg adjustment system for the toilet, which can be easily used in the assembly construction of the toilet, with honicel special honeycomb plate sealant adhesive, can be waterproof, moisture-proof and anti-leakage.

When ceramic plate is used in kitchen and bathroom system and other application scenarios, its main technical requirements are the impact resistance and bending strength of the table, and the excellent characteristics of Honicel rock plate just enhance the impact resistance and bending resistance of the rock plate.

Because the honeycomb structure provides honicel rock board with the characteristics of lightweight and bending resistance, lightweight and high strength honicel rock board has an excellent application prospect for high cabinet door products used in household wardrobe.

In the external wall application, the high strength and light weight honicel rock plate is also very suitable for the external wall dry hanging system, and its application prospect is very broad.

Because of the super physical characteristics of the rock plate, combined with the unique characteristics of honicel rock plate, honicel rock plate has a very broad space for development in the external wall dry hanging system.

Honicel rock board overcomes the disadvantages and pain points of ultra-thin rock board being fragile, difficult to transport and difficult to install on the wall, providing a new product and a new choice for building decoration and home decoration materials.

Installation of Honicel slab

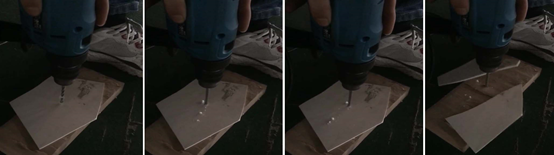

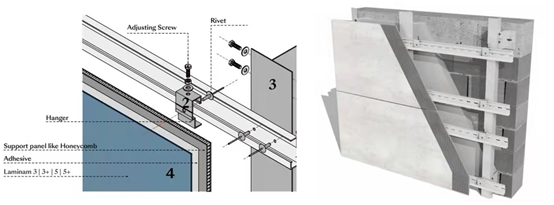

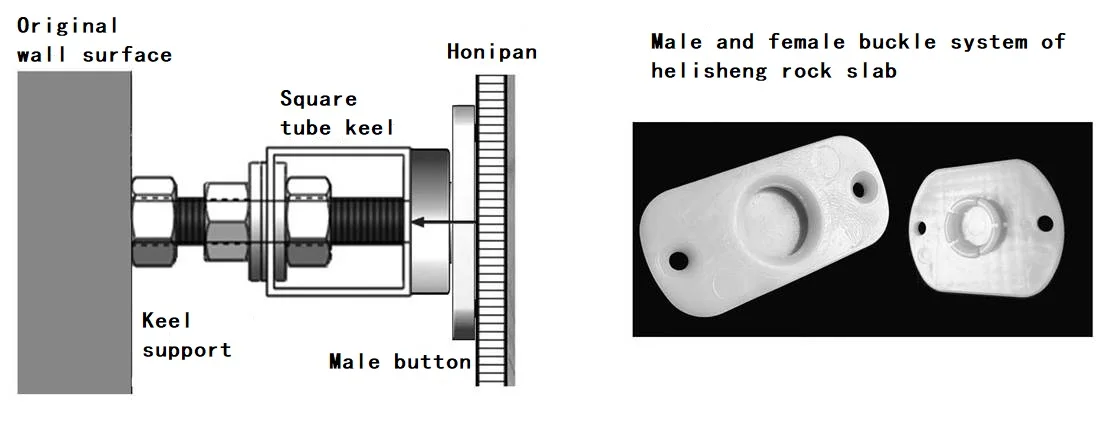

Honicel rock board dry hanging system adopts honicel rock board male and female fastener dry hanging system independently developed by Honicel company. Honicel rock plate fastener system is composed of special keel assembly for wall panel leveling, keel female buckle and honeycomb panel male buckle.

The special leveling keel assembly is installed on the original wall surface

with expansion screws, and the vertical plane of the keel can be accurately

adjusted. The female buckle of the wallboard is fixed on the keel in advance. On

the spot, the Honicel rock plate is accurately aligned to obtain the accurate

position of the positioning needle on the honeycomb plate surface, and the male

buckle is fixed by glue riveting. Finally, the male buckle of Honicel rock plate

is placed on the female buckle of the keel to complete the installation.

Honicel rock board dry hanging technology can realize repeated disassembly and assembly and use, which is convenient for later maintenance and replacement, safe and fast, especially suitable for prefabricated dry construction and installation, and truly realize the prefabricated installation method advocated by the State Housing and Construction Commission.

The honeycomb material expert at your side

Honicel honeycomb has been consistent for 26 years, focusing on the research and development of honeycomb materials, with excellent quality, quality service, has won the recognition and support of consumers from all walks of life.

We always adhere to improve quality by science and technology, win the market by quality, promote development by innovation, worthy of the title of 'honeycomb material industry revolution' technology pioneer and industry leader.

The last

We meet you at Guangzhou Design Week

Room 4C10, Hall 4, Poly World Trade Expo, Guangzhou

Be there or be square!